C Sharps Arms

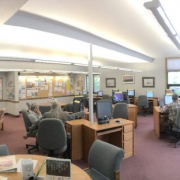

The C Sharps Arms building is located in Big Timber, Montana, and is used to produce custom firearms. The building is divided into two sections, the workshop and the retail/office space. The workshop is the largest section, accounting for approximately 11,100ft2. The building has high ceilings throughout both the workshop and retail spaces, while the offices are standard height with storage above. The basement is used as a packaging area and shooting range to test the company’s products.

Workshop lighting was the main concern for both the management team and the craftsmen. Lighting consisted of (101) 8-foot, two-lamp T12 fluorescent fixtures and (16) 4-foot, two-lamp T12 fixtures. Only 26 of the 8-foot fixtures and nine of the 4-foot fixtures were working or had bulbs. The goal of the management team was to increase lighting in the work areas, while leaving the unused areas dim. There is a second building that had (6) 8-foot fixtures, of which only three were working. The office and retail lighting was also out-of-date, but this was a secondary concern to the workshop. With this type of situation, it was recommended to do a complete replacement of the light fixtures. The table below shows the recommended replacement fixtures.

| Current Fixture | Number of

Fixtures |

Current

Wattage |

Replacement Fixture | Replacement

Wattage |

Watts

Saved |

| Exterior Wall Packs | 5 | 150 | LED Wall Packs | 30 | 120 |

| 4ft Fluorescent T12 | 79 | 80 | T8 18W LED Tube | 36 | 44 |

| 8ft Fluorescent T12 | 39 | 257 | LED High Bay Fixture | 119 | 138 |

| CFL Floods | 9 | 26 | 18W LED Flood | 18 | 8 |

| Halogen MR16 | 4 | 50 | 7.5 Watt LED | 7.5 | 42.5 |

Based on these upgrades, this project was eligible for $7,575 through a utility lighting rebate program. The rebates dropped the net project cost to $4,407. Annual energy cost savings was $2,391, for a simple payback of less than two years.

| C Sharps Arms | Annual

Bill Savings |

Est. Project

Cost |

Est.

Rebate |

Net

Cost |

KWh

Savings |

kW

Savings |

Simple

Payback |

| LED

Conversion |

$2,391 | $11,982 | $7,575 | $4,407 | 18,373 | 8.9 | 1.84 years |